Samples

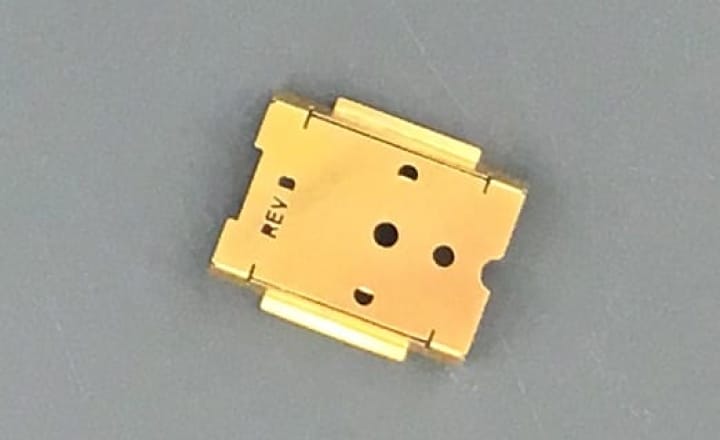

Photo chemical etching samples

We supply a wide variety of precision metal components for products and applications in the most demanding industries.

Custom capabilities with unrivaled precision

We know that your success depends on precision-accuracy from every component. Whether you need traditional parts, a unique prototype, or a custom design, we have the capabilities to produce precise metal parts that meet your exact requirements and industry-specific standards.

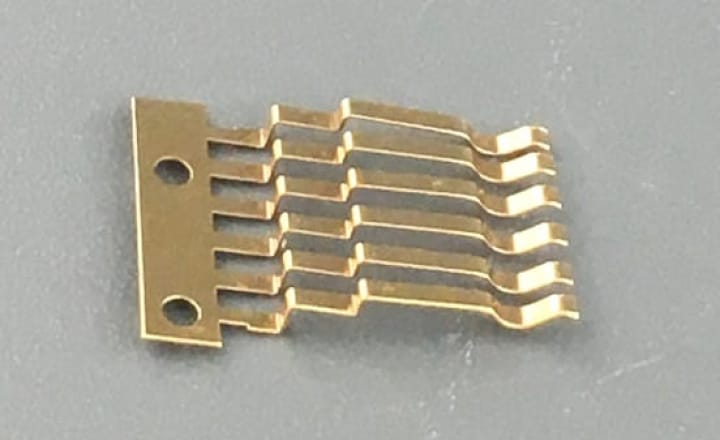

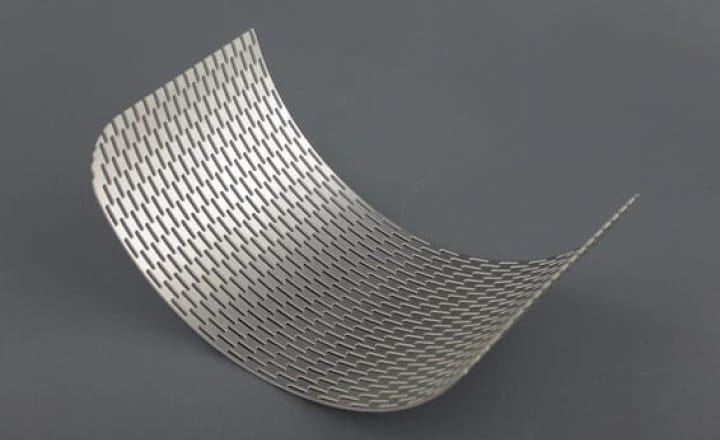

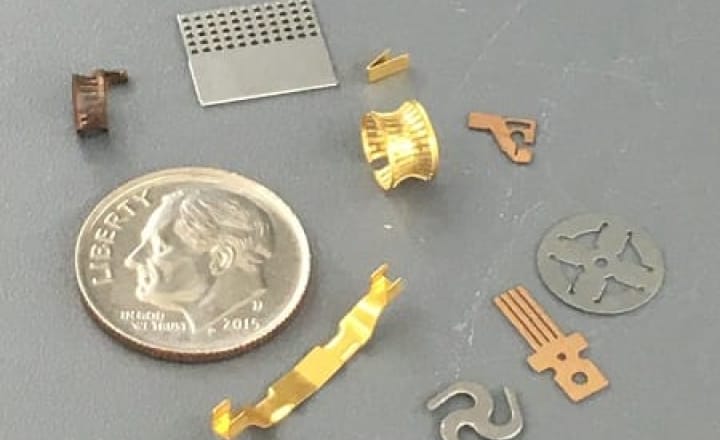

Examples of photo chemical etching

As a market leader in photo chemical etching, Vaga Industries takes pride in producing a diverse array of burr and stress-free components of unmatched accuracy and integrity with some of the shortest lead times in the industry. We supply:

- Shims

- Springs

- Decorative panels

- Prototypes

- Electrical contacts and connectors

- Encoder discs

- Nozzle adaptors

- Optical kickstands

- Screens

- Cable clips

- Cover plates

- Switches

- Filter components

- Heat sinks

- Metal gaskets

- Apertures

- Custom components

Etching 2000+ metals and alloys

Photo chemical etching is a versatile process that can create highly accurate metal parts and custom designs from virtually any metal with unlimited design complexity. At Vaga Industries, we offer:

- Stainless steel photo etching

- Aluminum photo etching

- Copper photo etching

- Titanium photo etching

- Beryllium copper photo etching

- Brass photo etching

- Inconel photo etching

- Molybdenum photo etching

- Custom metal etching

Photo chemical etching FAQs

Sheet metals of a thickness between 0.010 mm and 2.5 mm, and up to 600 mm x 1500 mm in size are within the range of chemical photo etching. It takes longer to etch thicker parts, so metals thicker than 2.5 mm can be cost-ineffective to process.

Photo chemical etching is a highly precise process and often the most cost-effective method for creating intricate features. The standard minimum etching tolerance is either ±10% of the metal thickness, or ±0.020 mm, whichever is greater. We recommend a free consultation with our engineers from the start of the design process, as our collaborative approach can guarantee results that meet your specific requirements.

- Photo chemical etching can be very accurate at high levels of detail

- Feature size: Depth-etched features can achieve a minimum standard feature size of 0.1 mm

- Holes and openings: 0.1 mm, or 80% of the material’s thickness

- Edge dimensions: Within ±10% of the part’s thicknes

Photo chemical etching is a scalable process without maximum production quantities.. At Vaga Industries, our production capabilities range from one-off prototypes to millions of units, with each component receiving the same level of precision and quality. This is because low-cost digital tooling enables a single design to be repeated without tooling wear.

Factors such as material type, thickness, and component size all impact the cost of photo chemical etching. For example, thicker sheet metals take more time to etch. Thin sheets or detailed projects may involve additional processing steps. Standard materials like stainless steel are less expensive than exotic alloys. Each of these factors can lead to higher overall costs per component. At Vaga Industries, our team of experienced specialists can guide you through these considerations to ensure the lowest cost and best possible outcome for your project.

Lead times for photo chemical etching are measured in days instead of weeks or months. Vaga Industries can supply standard components that require no additional post-processing in under two working weeks, depending on material availability and production capacity. If you have an urgent timeline, we can expedite the process for even faster turnaround.

Nozzle Adaptor

Optical Kickstand

Screen

Cable Clip

Spring

Mixed Parts

Cover Plate