Our photo etched prototype process

- Share your design for review

- Our engineers will create a detailed CAD model specifying dimensions, tolerances, material properties, and features.

- Expert consultation

- Talk with our expert team about your needs, budget, and goals, then receive an initial estimate.

- Engineering review

- We work with you to refine your design for feasibility, performance, and cost-effectiveness given your production goals and timeline.

- Design approval

- We submit our prototype plan and pricing to you before we begin

- Controlled run

- We can print multiple designs in a single print run, so you can see more iterations and get to market faster

- Post processing

- We offer a wide range of secondary services like heat treating and plating to streamline your supply chain and deliver designs to your exact specifications

- Pre-production

- Once you’re satisfied, we’ll discuss how to produce your part as quickly and cost-effectively as possible, and your specific supply chain considerations

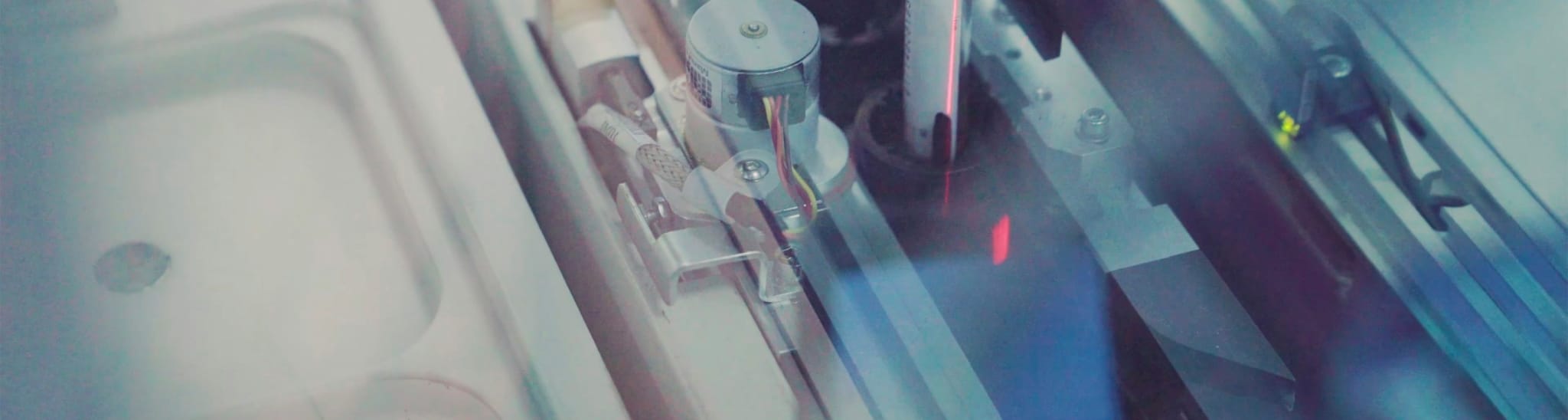

Versatile, rapid prototyping

Let us bring your design to life with levels of accuracy, speed, and affordability that traditional machining methods can’t match. We combine our chemical photo etching service with low-cost digital tooling to deliver components of unlimited complexity from a wide range of metal materials with accuracy within ±0.020mm [0.0005″] of your design specifications.

Our process for photo etched prototypes involves selectively removing material from sheet metal with chemical solution and UV photoresist, so there’s zero possibility of burrs, stress, or deformation. The result is a highly precise, cost-effective design iteration that retains its unique properties at high-production volumes.

Photo etched prototype benefits

- 100% burr and stress-free

- Accurate within ±0.020mm [0.0005″]

- Low-cost design iterations

- Unlimited design complexity

- Turnaround time in days

- Works with most metals

Prototype materials

Photo etched prototypes can be created from virtually any metal and alloy, regardless of their hardness, temper, or brittleness. We stock a variety of metals from 0.0002” to 0.062” in thickness and can source most materials for you. Our capabilities also allow us to work with any material you bring us.

Photo etched prototypes

We provide complex, burr and stress-free prototypes to your exact specifications in as little as a few days.