Home > Photo Etching Metal > Brass Photo Etching

Brass Photo Chemical Machining

Brass Photo Etching for Precision Parts

Brass is an alloy material made by combining copper and zinc in varying proportions. Different alloys and grades of brass exhibit different characteristics, but all provide high strength and hardness, excellent electrical and thermal conductivity, good ductility, and high corrosion resistance.

These unique characteristics make brass an excellent material for parts for a broad range of industries and applications. The Vaga Industries team has extensive experience in photo etching brass and can use this process to deliver the custom parts you need. Request a quote today or contact us to learn more.

Vaga Industries’ Brass Photo Etching Services

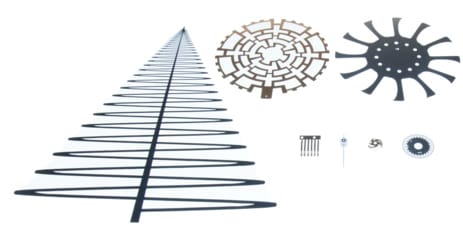

Using photo chemical machining, Vaga Industries produces high precision, tight tolerance brass parts. . All our brass parts are completely custom, and made to match the unique designs of our customers. Brass is available in numerous alloys and grades, and we can help you select the ideal variety for your specific needs.

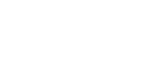

Photo chemical machining is a highly repeatable, cost effective method of producing brass parts in high or low volumes, as well as prototype parts. We can produce simple or complex parts that are burr-free and have no work hardening, no heat affected zones, and unaffected surface finishes. We can also use half or partial chemical etching processes to add intricate details, such as logos or lettering that vary in thickness but do not cut completely through the material.

We stock a large inventory of brass, in various alloys/grades, and can provide all the materials required for your project. We can also work with customer-supplied materials in our brass photo chemical machining processes.

Request a quote today, or contact Vaga Industries for more information on our capabilities for photo chemical machining brass.