Medical Components

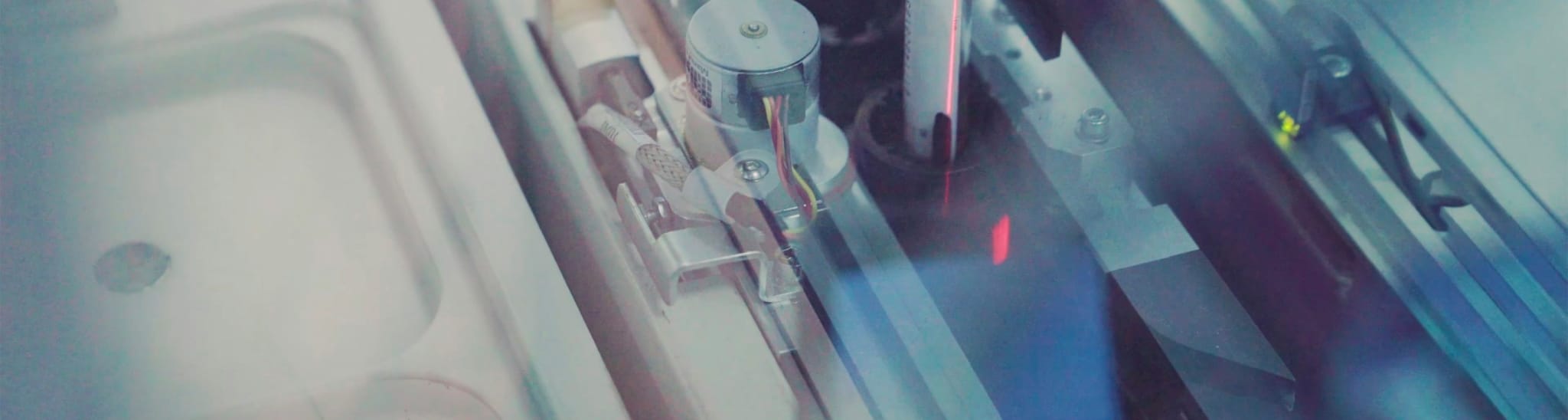

Creating complex, cost-effective components from a wide variety of medical-grade materials with chemical photo etching.

When it comes to medical devices, there’s no room for error. Every part has to be exactly right, every single time.

From parts for pacemakers to implantable monitoring devices and everything in between, photochemical etching gives you the precision you’re looking for. You get components that meet or exceed the tight tolerances required by medical OEMs, made with almost any metal you spec, including bio-compatible materials like titanium, platinum, nitinol and tantalum.

Contact us to request a quote. We’ll save you time, money and stress. So you can focus on saving lives.

A trusted supplier of medical components

Vaga Industries is committed to upholding the rigorous standards for quality control and compliance for the medical industry. With our market-leading chemical etching process, we deliver precise, cost-effective, and innovative components to many of the leading names in the medical industry.

Precise, reliable manufacturing

Our chemical photo etching service is ideal for medical manufacturing, creating 100% stress, burr, and distortion-free components through a non-thermal, non-contact process.

This ensures the delivery of components of the highest quality, precision, and repeatability, making chemical etching a more precise, cost-effective, and scalable option than traditional manufacturing processes.

Photo chemical etching benefits

- 100% burr and stress-free components

- Precision accuracy within ±0.020mm [0.0005″]

- Wide range of medical-grade materials

- Fast, low-cost prototyping

- Flexible mass production

Medical components

Our expertise with medical manufacturing extends to a wide range of medical components, from pacemakers to implantable monitoring devices to surgical instruments. We also offer post-processing services such as passivation, laser marking, and electropolishing to enhance the functionality, biocompatibility, and safety for medical applications.

- Custom metal shims

- Flat springs

- Prototypes

- Electrical interconnects and contacts

- Encoder discs

- PCB shielding cans

- Filters, sieves, screens

- EMI shielding

- Pacemakers

- Surgical instruments

- Implantable monitoring devices

Medical-grade materials

Our team of engineers offers decades of experience working with metals and alloys of various grades and types commonly used in medical components.

Our versatile chemical photo etching service makes use of stainless, ultra-hard steels for instruments, copper alloys, even biocompatible metals for stents, implants, and more.

View accreditations

Our team of engineers offers decades of experience working with metals and alloys of various grades and types commonly used in medical components.

Our versatile chemical photo etching service makes use of stainless, ultra-hard steels for instruments, copper alloys, even biocompatible metals for stents, implants, and more.

Five reasons the world’s most demanding engineers trust Vaga.

Precisely perfect

Burr-free, stress-free parts without the deformation other manufacturing processes can cause.

Quality at any quantity

Get exact repeatability over runs of 100,000 or more. Or cost-effectively produce just a few critical custom parts.

Verified manufacturing

Our photochemical etching process is ISO 9001 and AS9100 certified.

Prototyping and design help

Our experts can help you experiment and draft detailed specs.

Made in the USA

We’ve been building a legacy of world-class service since 1968, shipping globally from our workshop in California.