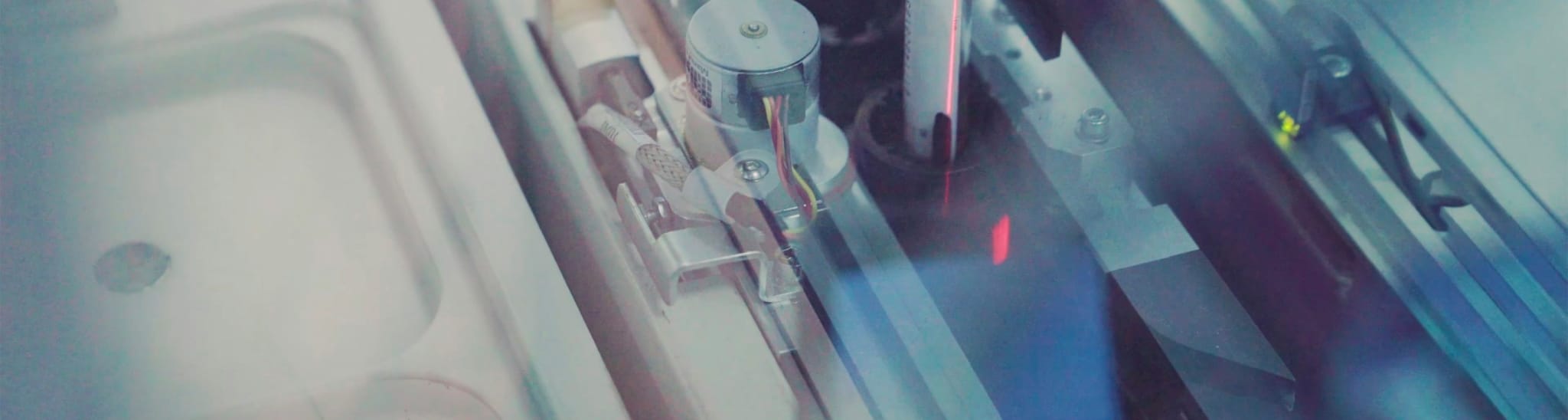

Photo etched electrical contacts

Supplying complex, miniaturized electrical contacts of the highest precision for a wide variety of high-tech applications.

What are electrical contacts?

Electrical contacts are conductive components that ensure the reliable transmission of electric signals between two devices. Designed to accommodate movement and stress, they can be manufactured as flat pieces, springs, or sliding contacts to suit various applications, even those with microscopic specifications.

Precision electrical contacts

We create photo etched electrical contacts that are 100% free of burrs, stress, and material degradation.

Unlike conventional machining methods such as stamping, our chemical photo etching process selectively removes material from sheet metal using chemical solution and UV photoresist—eliminating any possibility of burrs or stress—while enabling the most complex geometries and tightest tolerances within ±0.020mm of accuracy.

Economical, efficient tooling and production

Our chemical etching process replaces the expensive hard tooling of traditional methods with low-cost digital tooling, making it a more economical and efficient option for precision applications.

Digital tooling creates accurate component designs of perfect repeatability, accelerating lead-times and reducing costs whether you need a single prototype or 1,000,000 units. Vaga Industries can accommodate small and large-scale production runs with equal efficiency, and at a fixed price—supporting low-risk development strategies and rapid time-to-market needs.

Benefits of photo etched electrical contacts

- 100% burr and stress-free

- Suitable for most metals

- Unlimited design complexity at fixed cost

- Accuracy within ±0.020mm [0.0005″]

- Fast, low-cost prototyping

- Scalable mass production

Versatile range of materials

While traditional machining can struggle with hard, soft, and brittle metals ideal for electrical contacts, chemical etching is suitable for a wide range of metal types. Whether you require highly conductive copper, corrosion-resistant brass, or new alloys, we work with the full spectrum of materials to deliver photo etched electrical contacts of unrivaled accuracy and performance. You can learn more about our materials below.

Post processing services

We offer a comprehensive range of forming and finishing processes for photo etched electrical contacts, such as electropolishing, electroplating, and more. These value-added services help to simplify your supply chain and ensure optimal component performance and durability, even in the most extreme conditions.